Description

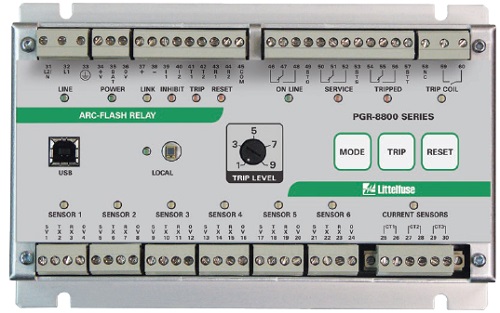

The PGR-8800 is a microprocessor-based relay that limits arc-fault damage by detecting the light from an arc flash and rapidly tripping. Phase-current-transformer inputs are provided for current-constrained arc-flash protection and, when so equipped, a programmable definite-time overcurrent function can be enabled. An optical sensor on the PGR-8800 and adjustable trip level reduce the chance of nuisance tripping by setting a threshold for ambient light. Sensors, inputs, and connections are monitored to ensure fail-safe operation. A secondary solid-state trip circuit provides a redundant trip path. A USB port is used for configuration and access to event logs and graphs.

Arc-Flash Detection and Response in less than 1ms

Arc-Flash Relay saved a plant from catastrophic damage

Optical Sensors

The PGR-8800 accepts both PGA-LS10 and PGA-LS20/ PGA-LS30 optical sensors, designed to collect light over a wide angle and with high sensitivity. For fast fault location, front-panel and sensor LED’s indicate sensor health and which sensor detected an arc fault.

Sensor Placement

The PGR-8800 Arc-Flash Relay and sensors are easily installed in retrofit projects and new switchgear with little or no re-configuration. Even elaborate systems with multiple power sources take minutes to configure using the relay’s built-in USB interface software.

Generally, it is recommended to mount 1 or 2 sensors per cubicle to cover all horizontal and vertical bus bars, breaker compartments, drawers, and anywhere that there is potential for an arc-fault. Threading a fiber-optic sensor through the cabinets and in areas where point-sensor coverage is uncertain results in complete coverage and an added level of redundancy. Even if policy is to only work on de-energized systems, all maintenance areas should be monitored to prevent potential damage and additional cost. At least one sensor should have visibility of an arc fault if a person blocks the other sensor(s).

Features & Benefits

Arc-Flash trip time <1 ms

Limits arc-flash damage and risk of injury

Multiple sensors (up to 24)

Single module can monitor 6 sensors. Up to 4 PGR-8800 units can be linked into one system

Fail-safe system

Continuous monitoring of optical sensors and inputs ensures protection

Redundant trip circuit

Solid-state backup arc-detection circuit adds a second layer of safety

Adjustable light sensitivity

Allows for operation in bright environments and maximum sensitivity in dark environments

LED indication (on unit and each sensor)

18 LEDs provide at-a glance status for module and I/O state

Current detection

Phase-CT inputs provide overcurrent protection and prevent nuisance trips

Optical detection

Point and fiber-optic sensors provide wide detection area with sensor health trip indication

Digital inputs (6)

Two each: remote trip, inhibit, and reset inputs

Service mode

Allows for system test without tripping

Trip coil contact

Solid-state 24-300 Vdc/24-300 Vac IGBT

Indication contacts

Form C and status outputs

USB interface

Data logging and configuration software uses a USB interface with no drivers or software installation

Built-in sensor

Can be used in single-sensor systems, as a seventh sensor, and for calibration

Universal power supply/Battery backup

100-240 Vac, 14-48 Vdc, or 110-250 Vdc supply accepted. Ability to charge and run off an external, user-supplied 24 Vdc battery.

Data logging

On-board event recorder helps with system diagnostics

Modbus

Remotely view measured values, event records & reset trips

Upstream Tripping

Ability to trip upstream device if the local breaker fails to clear the fault

Datasheets & Manuals

PGR-8800 Datasheet

PGR-8800 Manual

Littelfuse Arc-Flash Relay Brochure

Littelfuse Arc Flash Energy Reduction Workbook

Littelfuse Arc-Flash Relay FAQ

PGR-8800 Arc-Flash Relay Application Guide

Arc-Flash Case Study

Protection Relays Line Card