top faqs

Power Factor is a measure of how effectively incoming power is used in your electrical system and is defined as the ratio of Real (working) power to Apparent (total) power.

Real Power (KW) is the power that actually powers the equipment and performs useful, productive work. It is also called Actual Power, Active Power or Working Power.

Reactive Power (KVAR) is the power required by some equipment (eg. transformers, motors and relays) to produce a magnetic field to enable real work to be done. It’s necessary to operate certain equipment but you don’t see any result for its use.

Apparent Power (KVA) is the vector sum of Real Power (KW) and Reactive Power (KVAR) and is the total power supplied through the power mains that is required to produce the relevant amount of real power for the load. Let’s look at a simple analogy in order to better understand these terms.

Let’s say you’ve ordered a glass of your favourite beer. The thirst quenching portion of your beer is represented by Real Power (KW). Unfortunately, along with your ale comes a little bit of foam that doesn’t quench your thirst, represented by Reactive Power (KVAR). The total contents of your glass (KVA) is this summation of KW (the beer) and KVAR (the foam). The power factor is the ratio between Real Power and Apparent Power. It’s expressed as a value between -1 and 1 and can be either inductive (lagging) or capacitive (leading). If the power factor is 1, then all of the power supplied is being used for productive work and this is called ‘unity’.

Therefore, for a given power supply (KVA):

- The more foam you have (the higher the percentage of KVAR), the lower your ratio of KW (beer) to KVA (beer plus foam). Thus, the poorer your power factor.

- The less foam you have (the lower the percentage of KVAR), the higher your ratio of KW (beer) to KVA (beer plus foam) and the better your power factor. As your foam (or KVAR) approaches zero, your power factor approaches 1.0 (unity).

A power factor of -0.7 for example, indicates that only 70% of power supplied to your business is being used effectively and 30% is being wasted. The wasted power is the Reactive power (the foam in the previous example). Most loads are inductive in nature, which means the power factor will typically be less than unity. The further the power factor is from unity, the greater the apparent power drawn and therefore, the greater the current draw for the system.

The increased current may require an increase in the size of your transformers and installation power wiring. Increased current also results in increased heat which affects the longevity and lifespan of an electrical system. This can add a great deal of cost to the installation and may also limit the expansion of a plant.

It’s important because you may be paying for reactive power (foam) that you cannot use to power equipment. If you can reduce the foam, you can get more ‘beer for your buck’. Improving the power factor results in less current being drawn, therefore less electricity costs, less heat and greater longevity of the electrical system.

Many power suppliers charge for the base load (kW) and a maximum demand tariff. If this maximum demand tariff is measured in kVA, then improving the power factor reduces the kVA of

the installation, thus reduces the maximum demand tariff and thereby reducing your power costs.

It is actually a network regulation that customers maintain a specific minimum power factor (values depend on your region). Utility companies may charge customers a penalty on top of consumption charges when customer power factor is less than a determined value.

Poor Power Factor can be improved by installing Power Factor Correction (PFC) equipment. Traditional solutions incorporate banks of capacitors that work as silent reactive power ‘generators’, often housed in a metal cabinet similar to the one that houses your electrical switchboard. Fuseco offers the latest generation of advanced performance PFC solutions that do not need a capacitor bank and offer many advantages due to their compact and modular configuration.

An electrical load with a poor power factor draws more current than a load with an improved power factor for the same amount of useful power transferred and can put unnecessary strain on the electricity distribution network. By improving your power factor, you can reduce your electricity bills through lower monthly demand and capacity charges. Typically payback periods for power factor correction are between 1-3 years. Given the life expectancy of power factor correction equipment and the potential savings, it can be a very worthwhile investment. Poor power factor may cause power losses and voltage drops, which can contribute to overheating and failure of motors and other equipment. If your electrical system is near capacity, installation of power factor correction equipment may help avoid costly infrastructure upgrades by lowering the existing electrical demand on your system and improving efficiency stability.

Due to the operational temperature and safety requirements applicable to capacitor banks, traditional PFC systems are constructed as a separate, stand-alone assembly or in self-contained spaces within the overall construction of the main switch board. This results in the common situation where PFC systems occupy a large space, often taking up valuable floor space in switch rooms.

Sinexcel have applied new generation thinking and innovative design principles to create a new generation of PFC solutions that do not use a switched capacitor bank system. This has redefined what is possible from a cost vs performance vs space perspective.

Sinexcel SVG are a modular design that are available in wall-mount, rack-mount and rack/cabinet configurations. This flexibility gives engineers multiple options to cater for all situations and ultimately save valuable space and floor real-estate.

Compensating kVAr Capability vs Space

- Up to 100kVAr capability from a wall-mount solution

- Up to 100kVAr capability from a single rack-mount module

- Up to 400kVAr capability from a single standard cabinet solution

- Up to 600kVAr capability from a single ‘drawer-type’ cabinet solution

Knowledge Centre

Injection moulding business in Brisbane

An injection moulding business based in Brisbane engaged Fuseco to investigate ways to reduce the cost of their electricity expenditure. Their operation is a good example of a dynamic medium sized engineering facility. After conducting a site visit and analysing their power quality, it became apparent that correcting their power factor would yield significant savings. A saving of over $1,000 per month was achieved!

Injection moulding business in Brisbane

An injection moulding business based in Brisbane engaged Fuseco to investigate ways to reduce the cost of their electricity expenditure. Their operation is a good example of a dynamic medium sized engineering facility. After conducting a site visit and analysing their power quality, it became apparent that correcting their power factor would yield significant savings. A saving of over $1,000 per month was achieved!

THE CHALLENGE

Management felt that their electricity costs were too high and they wanted to investigate some options that would reduce their costs and result in a return on investment in under 3 years. As is commonly the case, the peak kVA Demand occurs during a combination of full production and office air-conditioning during the warmer months (Dec, Jan & Feb). Even if this peak kVA demand is only needed for 15 minutes, it becomes the peak kVA charge for the month (according to this particular billing contract used by their supply authority). Therefore, the company was still charged the maximum amount even in a very low load month. The challenge here was to find a way of saving money by lowering the peak kVA.

THE SOLUTION

The merits of power factor correction and solar power were investigated. A solar power solution was not selected as it usually provides benefit for an average of 4 hours a day over the 365 days of a year. This is due to cloud cover, bad weather and night-time which is particularly relevant when the operation is a double shift or 24 hour concern. Whereas power factor correction by using the Sinexcel SVG provides a 24-hour reduction in kVA consumption irrespective of the time of day or night and the weather conditions.

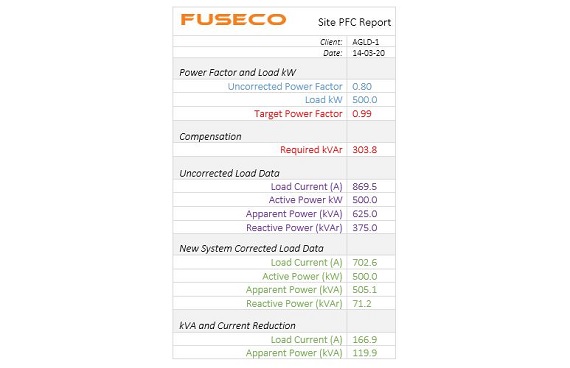

Analysis revealed that the site had a ‘real’ (kW) demand for electrical energy of 500kW and a power factor of 0.8. Power factor is expressed as kW/KVA, so the ‘apparent’ power required to produce this ‘real’ power was 500/0.8 = 625KVA. Improving the power factor will reduce this KVA and therefore reduce the supply transformer requirements or increase the available ‘real’ power from the transformer.

The Sinexcel Static Var Generator (SVG) provides for the greatest return by maintaining 0.99 lagging (or better) which allows the business to fully utilise the capacity of the supply transformer at all times. The required compensation was calculated to be 303.8kVAr. Fuseco provided three wall-mount SVG modules for installation (1 x 200kVAr, 1 x 100kVAr & 1 x 50kVAr), providing a total compensation capacity of 350kVAr. The wall mounting modules also saved valuable floor space in the company’s switch room.

THE OUTCOME

By using the Sinexcel SVG Power Factor Correction Equipment, the power factor was improved to 0.99, the apparent power required to produce 500kW of real power was reduced to 505KVA, a saving of 120KVA. At 415V 3-phase, this is a reduction in switchboard current to 166A per phase. The installation was being charged on a KVA demand basis, so a tangible saving was achieved. In this case, the KVA demand charge was $8.90/KVA/month, so the following was achieved:

- A reduction in electricity charges of $1,068 / month.

- A return on investment (ROI) well under 2 years.

- If your billing has changed to a kVA demand tariff and you have poor power factor, you are definitely paying for electricity that you are not using. In such cases, the SVG will reduce your electricity bills. Typically, most installations achieve savings of 10%-30%.

- No capacitor banks therefore no maintenance costs & performance issues associated with capacitors.

- Excellent power factor correction performance - Can maintain a PF of 0.99 lagging or unity if required.

- Dynamic Step-Less Compensation - Profiles the load and operates with a response speed of <15ms. No possibility of over or under compensation, will only inject the kVAr that is needed in that moment.

- Corrects load imbalance.

- Compensates both inductive and capacitive loads - corrects lagging and leading power factor.

- Can work with & enhance existing capacitor-bank based systems.

- Not affected by resonance.

- Can operate at low voltages.

- Excellent ROI (Return on Investment).

THE SINEXCEL SVG - BENEFITS

Simple PFC solutions incorporate banks of capacitors that work as silent reactive power ‘generators’. These systems were designed many decades ago when electrical environments were a lot simpler than they are today. They are common, very economical and suitable for linear load environments.

However, in today’s modern electrical environments, linear loads are not easy to find. Due to the proliferation of LED/energy efficient lighting, switch-mode power supplies, VSD’s, UPS’s, servers/computers and typical appliances, today’s electrical systems experience complex, dynamic non-linear loads. Loads are being switched so fast that the traditional capacitor bank PFC systems struggle to maintain an effective compensation set-point. Therefore, they are perpetually ‘chasing’ the load, either under or over-compensating but rarely providing effective compensation.

Fuseco offers the latest generation of advanced performance PFC solutions that offer instantaneous, dynamic step-less compensation, ideal for the challenging demands of modern electrical environments. The Sinexcel SVG solutions do not need a capacitor bank and offer many advantages due to their compact & modular configuration (including wall-mount options).

We're here to help

Talk to an expert today.

Our friendly team of highly trained specialists will quickly assist you.

We promise to respond within 4 business hours (AEST).

Or you will receive $100 off your next purchase. Read how it works.

From the moment the AHF and SVG units were turned on our power factor issues were a thing of the past. At both sites our PF is now 0.99 on all phases all the time, the units react instantaneously to our fluctuating load and power factor and the result has been an excellent return on investment.

Brad Kilner

OPERATIONS MANAGER AT KILNER'S ENGINEERING

The PFC units are now installed and running. They are doing a great job at maintaining a constant PF of 0.99 across all phases. Great product and excellent support from both of you. Very pleased doing business with you. Your help has been much appreciated.

Darren Brownscombe

ENGINEER AT TURBOSMART

Applicable Industries

Technical Support

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Technical supportTalk to an expert

Our friendly team are highly trained product experts who really enjoy helping customers find what they need.

call 1300 387 326Enquire by email

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase.

Enquire now