Cheers to Efficiency: Campari's Power Factor Success with Fuseco

Cheers to Efficiency: Campari's Power Factor Success with Fuseco

Located near Derrimut, Melbourne is a bottling & distribution facility of the timeless classic brand Campari. The electrical engineering team on site suspected that they had poor power factor, a fact that was confirmed once they conducted their power quality measurements. They calculated that a 350kVAr solution would be required and reached out to Fuseco for advice. The installation of a Sinexcel SVG system transformed their electrical environment. It improved their power factor from around 0.84 to 0.99 and reduced the current by around 100 Amps per phase.

The Challenge

The Campari bottling and distribution facility is a dynamic environment with all the usual challenges associated with growth. The electrical systems have grown with the demand however the engineering team reached a point where they knew that opportunities existed to optimise the system and achieve some significant cost savings. Once they measured their power factor performance, it was clear that the addition of a 350kVAr system would reap dividends. After consulting with the Campari management, the Fuseco team proposed a Sinexcel SVG cabinet solution to be located near the main switchboards.

The Solution

Fuseco supplied a 350kVAr Sinexcel SVG cabinet solution (SVG-350-4-4L-RL). Most of the settings are pre-programmed at Fuseco's premises, so commissioning the unit at Campari's facility was relatively straight forward. The LCD screen is very easy to use and set up is virtually 'plug and play'. The Sinexcel rack-mounted modules within the cabinet can be parallel connected in a ‘Master / Master’ type arrangement, which provides the safest continuous operation. If one unit is shut down for whatever reason the remaining modules remain in operation until the alarm is attended to, or the situation is resolved.

The Outcome

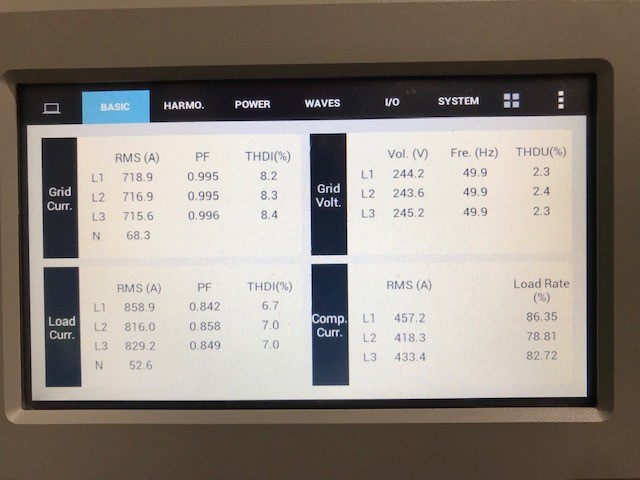

The addition of the Sinexcel SVG had a very positive affect on the electrical system. If we check the screenshot of the unit's LCD display, we can see that the power factor has improved from around 0.84 to 0.99. The current is now balanced across all three phases and has been reduced by around 100A. Campari reported post-installation that they were extremely happy with the cost savings achieved and were happily reporting that their power bills were significantly reduced.

Why Fuseco?

With a team of experienced professionals available to assist with any questions or concerns, Fuseco is dedicated to ensuring customers are completely satisfied with their purchases.

We're here to help

Talk to an expert today.

Our friendly team of highly trained specialists will quickly assist you.

We promise to respond within 4 business hours (AEST).

Or you will receive $100 off your next purchase. Read how it works.

No capacitor banks

SVG does not use AC capacitor banks so it does not have the reliability issues & ongoing costs associated with these.

Wall mounting solutions

At just 25kg, the 100kVAr Sinexcel P5 SVG wall mounted unit is the most compact power factor correction solution in the world. Wall mounted solutions free up valuable switch room floor space.

load balancing

By balancing the load across all three phases, the SVG reduces the peak current which in turn reduces the peak demand tariff (electricity bills) and the load on the switchboard.

dynamic stepless compensation

The SVG provides compensation instantaneously in real-time to each phase individually with no possibility of over-compensation or under-compensation.

our brand portfolio

Applicable Industries

Top FAQs

VIC - HEAD OFFICE / WAREHOUSE

27 Viking Court

Cheltenham VIC 3192

NSW - SALES OFFICE / WAREHOUSE

29/8-10 Barry Road

Chipping Norton NSW 2170

QLD - SALES OFFICE

1 / 26 Duke Street

Sunshine Beach QLD 4567

WA - SALES OFFICE

67 Howe Street

Osborne Park WA 6017

We'd love to hear from you! At Fuseco, rather than publish generic prices, we prefer to give you an individual quote. This ensures that we provide you with the best possible pricing to meet your needs.

The quickest way to place an order is to give our customer service team a call or send us an email. We promise to respond within 4 hours or you get $100 off your next order, however we usually respond within 1-2 hours to email enquiries. So go ahead and speak to us, we'd love to help you with your needs.

Fuse Products

- For all orders over $100 (excl. GST & freight), freight is FIS (Free into Store).

- For all orders under $100 (excl. GST & freight), a freight charge of $25 + GST is applicable.

- Additional fees may apply for deliveries to the Northern Territory and remote areas.

All Other Products

- Freight charges POA (Price on Application)

- FOT (Customer nominates own carrier and accepts all charges)

Power Factor is a measure of how effectively incoming power is used in your electrical system and is defined as the ratio of Real (working) power to Apparent (total) power.

Real Power (KW) is the power that actually powers the equipment and performs useful, productive work. It is also called Actual Power, Active Power or Working Power.

Reactive Power (KVAR) is the power required by some equipment (eg. transformers, motors and relays) to produce a magnetic field to enable real work to be done. It’s necessary to operate certain equipment but you don’t see any result for its use.

Apparent Power (KVA) is the vector sum of Real Power (KW) and Reactive Power (KVAR) and is the total power supplied through the power mains that is required to produce the relevant amount of real power for the load. Let’s look at a simple analogy in order to better understand these terms.

Let’s say you’ve ordered a glass of your favourite beer. The thirst quenching portion of your beer is represented by Real Power (KW). Unfortunately, along with your ale comes a little bit of foam that doesn’t quench your thirst, represented by Reactive Power (KVAR). The total contents of your glass (KVA) is this summation of KW (the beer) and KVAR (the foam). The power factor is the ratio between Real Power and Apparent Power. It’s expressed as a value between -1 and 1 and can be either inductive (lagging) or capacitive (leading). If the power factor is 1, then all of the power supplied is being used for productive work and this is called ‘unity’.

Therefore, for a given power supply (KVA):

- The more foam you have (the higher the percentage of KVAR), the lower your ratio of KW (beer) to KVA (beer plus foam). Thus, the poorer your power factor.

- The less foam you have (the lower the percentage of KVAR), the higher your ratio of KW (beer) to KVA (beer plus foam) and the better your power factor. As your foam (or KVAR) approaches zero, your power factor approaches 1.0 (unity).

A power factor of -0.7 for example, indicates that only 70% of power supplied to your business is being used effectively and 30% is being wasted. The wasted power is the Reactive power (the foam in the previous example). Most loads are inductive in nature, which means the power factor will typically be less than unity. The further the power factor is from unity, the greater the apparent power drawn and therefore, the greater the current draw for the system.

The increased current may require an increase in the size of your transformers and installation power wiring. Increased current also results in increased heat which affects the longevity and lifespan of an electrical system. This can add a great deal of cost to the installation and may also limit the expansion of a plant.

It’s important because you may be paying for reactive power (foam) that you cannot use to power equipment. If you can reduce the foam, you can get more ‘beer for your buck’. Improving the power factor results in less current being drawn, therefore less electricity costs, less heat and greater longevity of the electrical system.

Many power suppliers charge for the base load (kW) and a maximum demand tariff. If this maximum demand tariff is measured in kVA, then improving the power factor reduces the kVA of

the installation, thus reduces the maximum demand tariff and thereby reducing your power costs.

It is actually a network regulation that customers maintain a specific minimum power factor (values depend on your region). Utility companies may charge customers a penalty on top of consumption charges when customer power factor is less than a determined value.

Poor Power Factor can be improved by installing Power Factor Correction (PFC) equipment. Traditional solutions incorporate banks of capacitors that work as silent reactive power ‘generators’, often housed in a metal cabinet similar to the one that houses your electrical switchboard. Fuseco offers the latest generation of advanced performance PFC solutions that do not need a capacitor bank and offer many advantages due to their compact and modular configuration.

An electrical load with a poor power factor draws more current than a load with an improved power factor for the same amount of useful power transferred and can put unnecessary strain on the electricity distribution network. By improving your power factor, you can reduce your electricity bills through lower monthly demand and capacity charges. Typically payback periods for power factor correction are between 1-3 years. Given the life expectancy of power factor correction equipment and the potential savings, it can be a very worthwhile investment. Poor power factor may cause power losses and voltage drops, which can contribute to overheating and failure of motors and other equipment. If your electrical system is near capacity, installation of power factor correction equipment may help avoid costly infrastructure upgrades by lowering the existing electrical demand on your system and improving efficiency stability.

Due to the operational temperature and safety requirements applicable to capacitor banks, traditional PFC systems are constructed as a separate, stand-alone assembly or in self-contained spaces within the overall construction of the main switch board. This results in the common situation where PFC systems occupy a large space, often taking up valuable floor space in switch rooms.

Sinexcel have applied new generation thinking and innovative design principles to create a new generation of PFC solutions that do not use a switched capacitor bank system. This has redefined what is possible from a cost vs performance vs space perspective.

Sinexcel SVG are a modular design that are available in wall-mount, rack-mount and rack/cabinet configurations. This flexibility gives engineers multiple options to cater for all situations and ultimately save valuable space and floor real-estate.

Compensating kVAr Capability vs Space

- Up to 100kVAr capability from a wall-mount solution

- Up to 100kVAr capability from a single rack-mount module

- Up to 400kVAr capability from a single standard cabinet solution

- Up to 600kVAr capability from a single ‘drawer-type’ cabinet solution

Related Resources

From the moment the AHF and SVG units were turned on our power factor issues were a thing of the past. At both sites our PF is now 0.99 on all phases all the time, the units react instantaneously to our fluctuating load and power factor and the result has been an excellent return on investment.

Brad Kilner

OPERATIONS MANAGER AT KILNER'S ENGINEERING

The PFC units are now installed and running. They are doing a great job at maintaining a constant PF of 0.99 across all phases. Great product and excellent support from both of you. Very pleased doing business with you. Your help has been much appreciated.

Darren Brownscombe

ENGINEER AT TURBOSMART

Technical Support

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Technical supportTalk to an expert

Our friendly team are highly trained product experts who really enjoy helping customers find what they need.

call 1300 387 326Enquire by email

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase.

Enquire now