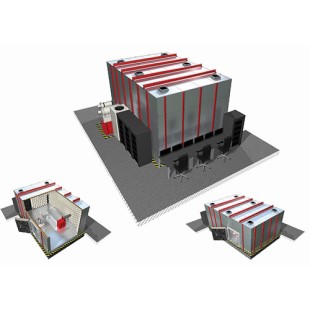

E-Drive Testing Chamber - EDTC

Frankonia’s e-drive testing chamber solution for powertrain components and systems related to hybrid, electric, fuel cell and battery drive systems.

Can we help you?

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase. Read how it works

- Radiated emissions (EMI):

Full compliance according to CISPR 25 - Radiated immunity (EMS):

Full compliance according to ISO 11452-2 - Complete range of powertrain components and complete systems in one chamber

- Cutting-edge test equipment for powertrain components and complete systems

- Automatized and customizable software solutions

- Reproducible test conditions

- Common DC-bus with battery simulation (reduces conversion loss)

- Highest quality and performance level up to 1,000 kW at 8,500 RPM

- Battery simulator up to 1,000VDC and up to 500A

- Conditioning unit for permanent temperature control and simulation from -20 °C up to +100 °C

- Highest European safety standards

- Can be used for non-EMC testing procedures

- Modification kit for existing chambers

- Compact chamber solution; upgradable for future tasks

- Optimized absorber lining with Frankosorb® long-lasting absorbers (Frankonia technology)

- EMC knowledge-exchange base and worldwide service

- Turn-key solution

The EDTC is Frankonia’s fully compliant e-drive and powertrain testing chamber solution that is designed for EMC components and system testing for all types of hybrid, electric, fuel cell and battery drive systems.

The term powertrain describes the main components that generate power and deliver it to the road, water or air. With its innovative concept and its optimized layout that is based on the ACTC (automotive components testing chamber), the EDTC offers superior conditions for radiation testing according to CISPR 25 and DIN/ISO 11452-2, and remarkable minimized reflections.

The chamber is lined with ferrite absorbers and partially lined with Frankosorb® hybrid absorbers to cover a frequency range from 150 kHz to 18 GHz (40 GHz as option) that offers outstanding performance.

| EDTC – Powertrain testing chamber | |

|---|---|

Technical specification | |

External dimension (L x W x H) | 7.880m x 5.330m x 4.050m (exemplary) |

Frequency range | 150 kHz to 18 GHz (option 40 GHz) |

Measuring distance | 1.0m |

Basement | Vibration-free and non-interacting solid basement (floating slab) |

Absorber lining | |

Walls and ceiling | Optimized lining with ferrite absorbers and Frankosorb® hybrid absorbers |

Floor | Highly conductive floor finish and protection |

EUT test table | According to CISPR 25, incl. drive unit bench and fixation set, and optional mobile absorbers |

EDTC - Performance | |

|---|---|

Emission test (EMI) | Full compliance according to CISPR 25 Ed. 4 (performance absorption material min. ≥6 dB) |

Immunity test (EMS) | Full compliance according to DIN/ISO 11452-2 (reduction of reflection in the test area min. -10 dB) |

EDTC – Powertrain component and system configurations | |||

|---|---|---|---|

Technical specification | |||

Version* | EDTC-250 | EDTC-500 | EDTC-800 |

Power range | 250kW | 500kW | 800kW |

Torque | 550Nm | 1,100Nm | 5,100Nm |

Revolution speed | up to 8,500 RPM | up to 3,500 RPM | |

Energy system | Dynamic DC-source/DC-sink; up to 1,000VDC and up to 500A; common DC-bus with dynamometer drive | ||

Conditioning unit | Liquid or air cooling and simulation for dynamometer drive and battery simulation from -20 °C up to +100 °C; Liquid cooling and simulation for e-motor (EUT) under test from -20 °C up to +100 °C | ||

Test solution | Powertrain components and system tests related to hybrid, electric, fuel cell and battery drive systems | ||

We're here to help

Talk to an expert today.

Our friendly team of highly trained specialists will quickly assist you.

We promise to respond within 4 business hours (AEST).

Or you will receive $100 off your next purchase. Read how it works.

Largest installation base in Australia

We bring to you the experience of having installed more EMC chambers in Australia than any other company.

Turn-key solution provider

Fuseco can build a complete end-to-end EMC chamber system with all the test equipment fully integrated or alternatively just the chamber or the test equipment.

Customer support

With our experience, brands, pricing levels, expertise and industry leading post-installation customer support, Fuseco have become the industry's most trusted partner for EMC testing.

our brand portfolio

Applicable Industries

Top FAQs

VIC - HEAD OFFICE / WAREHOUSE

27 Viking Court

Cheltenham VIC 3192

NSW - SALES OFFICE / WAREHOUSE

29/8-10 Barry Road

Chipping Norton NSW 2170

QLD - SALES OFFICE

1 / 26 Duke Street

Sunshine Beach QLD 4567

WA - SALES OFFICE

67 Howe Street

Osborne Park WA 6017

EMC means "an electronic or electrical product shall work as intended in its environment. The electronic or electrical product shall not generate electromagnetic disturbances (interference), which may influence other products". In other words, EMC deals with problems of noise emission as well as noise immunity of electronic and electrical products and systems. Electromagnetic disturbances occur as conducted interference as well as radiated emissions and immunity problems.

An anechoic chamber is a room designed to completely absorb reflections of electromagnetic waves used for various EMC Testing. They are also insulated from exterior sources of noise. The combination of both aspects means they simulate a quiet open-space of infinite dimension, which is useful when exterior influences would otherwise give false results. The RF anechoic chamber is typically used to house the equipment for performing measurements of antenna radiation patterns, electromagnetic compatibility (EMC) and radar cross section measurements. EMC chambers allow for the performance of fast and efficient EMC radiated tests at a convenient location, without interference from the ambient electromagnetic environment.

The term conducted emissions refers to the mechanism that enables electromagnetic energy to be created in an electronic device and coupled to its AC power cord. Similarly to radiated emissions, the allowable conducted emissions from electronic devices are controlled by regulatory agencies. If a product passes all radiated emissions regulations but fails a conducted emissions test, the product cannot be legally sold.

The term radiated emissions refers to the unintentional release of electromagnetic energy from an electronic device. The electronic device generates the electromagnetic fields that unintentionally propagate away from the device’s structure. In general, radiated emissions are usually associated with non-intentional radiators, but intentional radiators can also have unwanted emissions at frequencies outside their intended transmission frequency band.

Conducted Immunity (also called Susceptibility) is a measure of the ability of electronic products to tolerate the influence of conducted electrical energy from other electronic products and electromagnetic phenomena.

Radiated Immunity (also called Susceptibility) is a measure of the ability of electronic products to tolerate the influence of radiated electrical energy from other electronic products and electromagnetic phenomena.

Simulates disturbances created by radio transmitters operating below 80 MHz (such as AM broadcast transmitters) that would typically be coupled onto a products interface cables.

Test Method

The test signal, amplitude modulated by a 1 kHz sine wave, is injected onto the AC or DC wires via a Coupling, Decoupling Network (CDN) while the frequency is varied. Unshielded cables can be tested using either a CDN, coupling clamp or current injection probe. Shielded cables are tested using direct injection, the signal is coupled through a 100-Ohm resistor onto the shield of the cable under test. The injection level is pre-calibrated using the appropriate calibration jig and is equivalent to the open circuit voltage at the output from the amplifier for an unmodulated signal.

The test level for the residential, commercial and light industrial generic standard is 3 Volts; for heavy industrial equipment the test level is 10 Volts.

Related Resources

We have a Frankonia SAC3Plus EMC chamber that we use for commercial testing. We have some height limitations in our laboratory and its dome shaped design fits very conveniently. We are happy with the performance of the chamber and their absorber design is great. No carbon dust and falling of foam absorbers. Previously we had carbon foam-based absorbers and we literally had to wear a safety hat before entering the chamber.

Terry Stones

LABORATORY MANAGER

Technical Support

Our experts are all pre-eminent leaders in electrical products who provide excellent support in their areas of expertise.

Technical supportTalk to an expert

Our friendly team are highly trained product experts who really enjoy helping customers find what they need.

call 1300 387 326Enquire by email

We promise to respond within 4 business hours (AEST) or you will receive $100 off your next purchase.

Enquire now